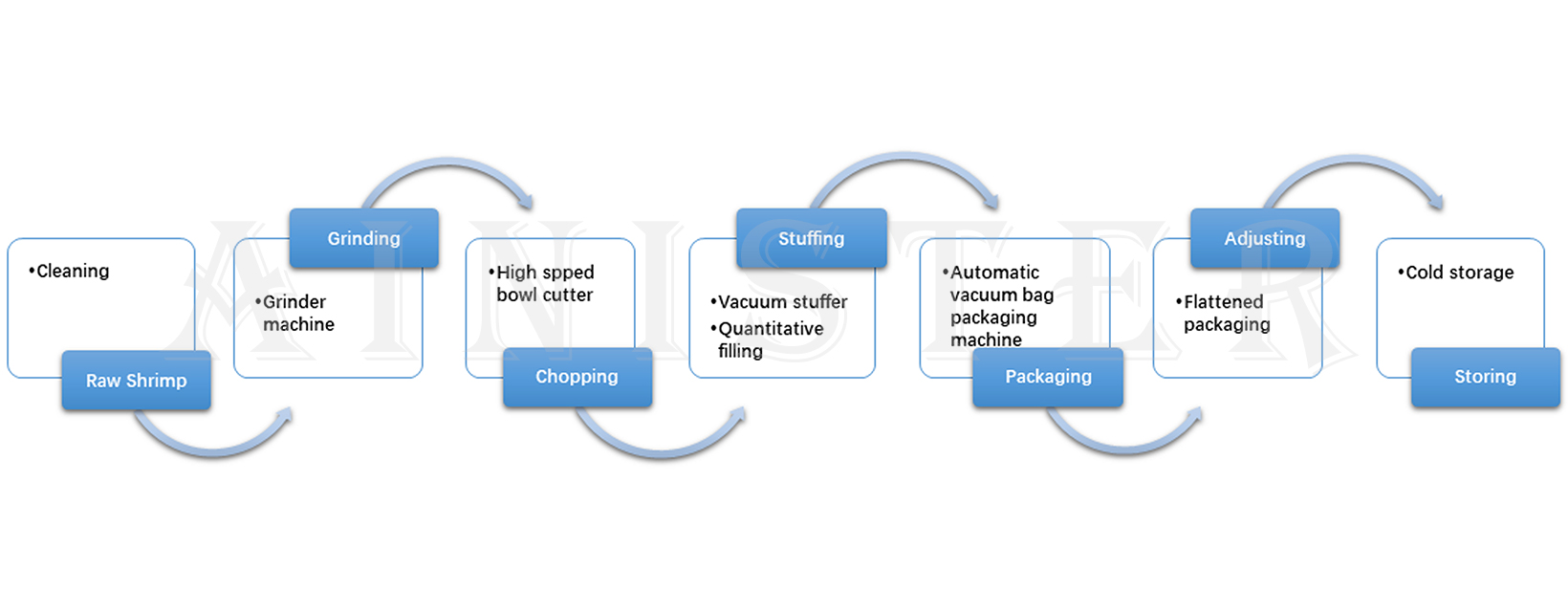

Shrimp Paste Production Line

Yuav ua li cas ua kom cw thiab ntses paste nrog lub tshuab nqus tsev tsis siv neeg?

Cov khoom siv Display

- 1. Compressed Cua: 0.06 Mpa

- 2. Chav Siab: 0.06-0.08 Mpa

- 3. Fais fab tuag: 3 ~ 380V / 220V Los yog Customized raws li qhov sib txawv voltages.

- 4. Muaj Peev Xwm Ntau Lawm: 200kg-2000kg ib teev.

- 5. Cov Khoom Siv: Cov kua txob ua kua txob.

- 6. Lub Sijhawm Warranty: Ib xyoos

- 7. Daim ntawv pov thawj zoo: ISO9001, CE, UL

1.Koj puas muab cov khoom lossis khoom siv, lossis kev daws teeb meem?

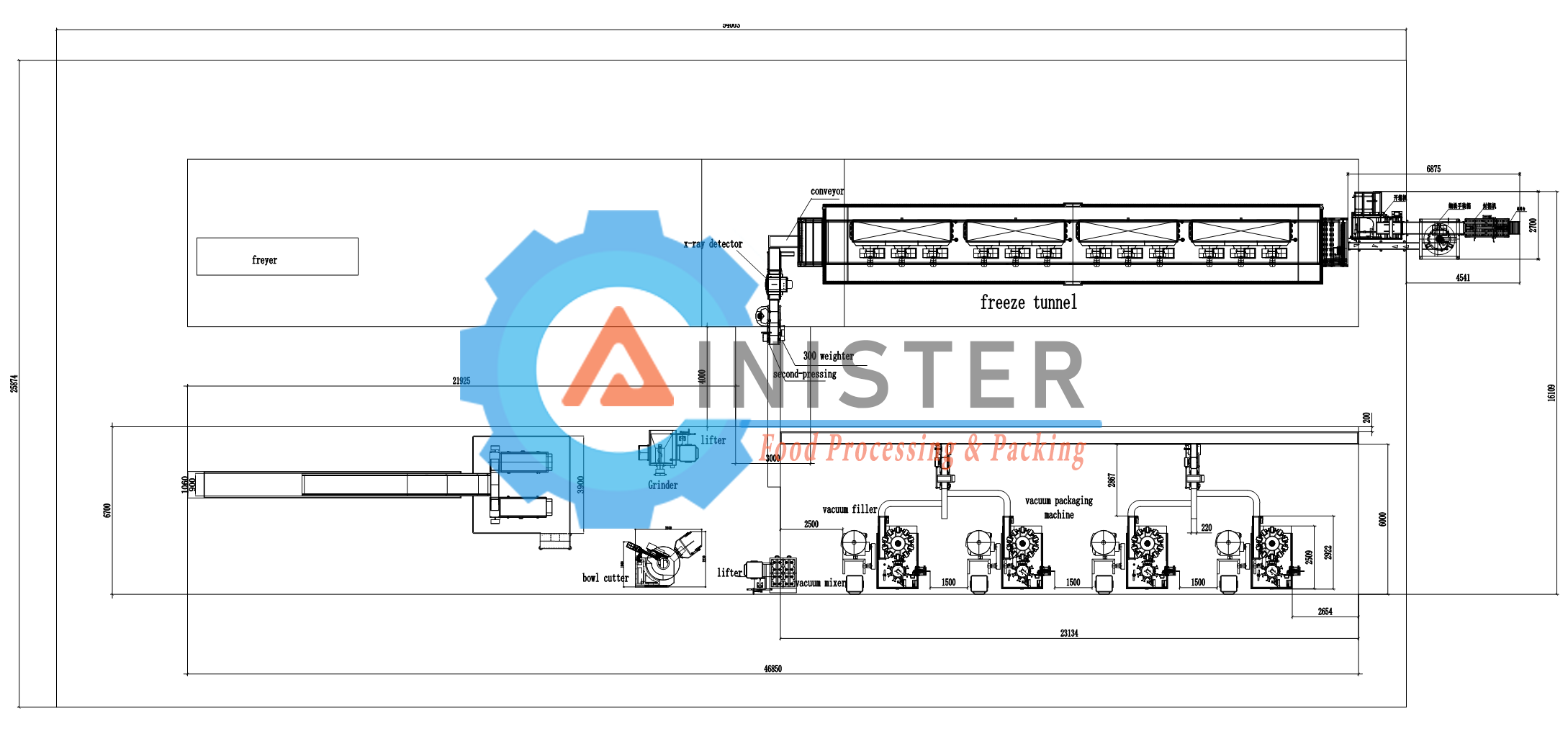

Peb tsis tsim cov khoom kawg, tab sis yog cov chaw tsim khoom ntawm cov khoom siv ua zaub mov, thiab peb kuj koom ua ke thiab muab cov kab ntau lawm rau cov khoom noj khoom haus.

2.Dab tsi ntawm koj cov khoom thiab cov kev pabcuam cuam tshuam nrog?

Raws li kev koom ua ke ntawm cov kab ntau lawm ntawm Pab Pawg Pab Pawg, peb tsis tsuas yog muab ntau yam khoom siv ua zaub mov, xws li: lub tshuab nqus tsev filling, chopping tshuab, tsis siv neeg xuas nrig ntaus tshuab, tsis siv neeg ci qhov cub, lub tshuab nqus tsev tov khoom, lub tshuab nqus tsev tumbler, khov nqaij / nqaij tshiab grinder, noodle ua tshuab, dumpling ua tshuab, thiab lwm yam.

Peb kuj muab cov kev daws teeb meem hauv qab no lub Hoobkas, xws li:

Sausage processing nroj tsuag,noodle ua cov nroj tsuag, dumpling nroj tsuag, cov kaus poom zaub mov ua cov nroj tsuag, tsiaj ua zaub mov, thiab lwm yam., koom nrog ntau yam khoom noj sib txawv thiab ntau lawm teb.

3.Lub teb chaws twg yog koj cov khoom xa tawm mus rau?

Peb cov neeg siv khoom thoob plaws ntiaj teb, suav nrog Tebchaws Meskas, Canada, Colombia, Lub Tebchaws Yelemees, Fabkis, Qaib ntxhw, Kaus Lim Qab Teb, Singapore, Nyab Laj, Malaysia, Saudi Arabia, Is Nrias teb, South Africa thiab ntau tshaj 40 lub teb chaws thiab cheeb tsam, muab cov kev daws teeb meem. rau cov neeg siv khoom sib txawv.

4.Yuav ua li cas koj lav lub installation thiab tom qab-muag kev pab cuam ntawm cov khoom?

Peb muaj ib pab neeg ua haujlwm paub txog thiab cov neeg ua haujlwm tsim khoom, uas tuaj yeem muab cov kev taw qhia chaw taws teeb, kev teeb tsa ntawm qhov chaw thiab lwm yam kev pabcuam.Pab pawg kws tshaj lij tom qab muag tuaj yeem sib txuas lus nyob deb ntawm thawj zaug, thiab txawm tias kho ntawm qhov chaw.